Agile WMS is the jewel in BaubleBar crown

Fast growing trend-led accessories brand, BaubleBar, has revolutionized its batch picking and single item orders – for much greater throughput – after switching up to cloud-based SnapFulfil.

The New York-based company, which specializes in affordable yet desirable statement jewelry, recently ditched its inflexible and expensive-to-modify warehouse management system (WMS) for Synergy’s functionally rich and highly configurable SnapFulfil solution.

Shipping around 30,000 orders per month from its 40,000 sq ft New Jersey distribution center, BaubleBar has achieved an outstanding 10-fold increase in its pick rate, whilst maintaining 100% accuracy, since implementing SnapFulfil. In addition to successfully scaling up its B2B and wholesale channels, the company has also experienced a 10%-30% jump in ecommerce/D2C sales.

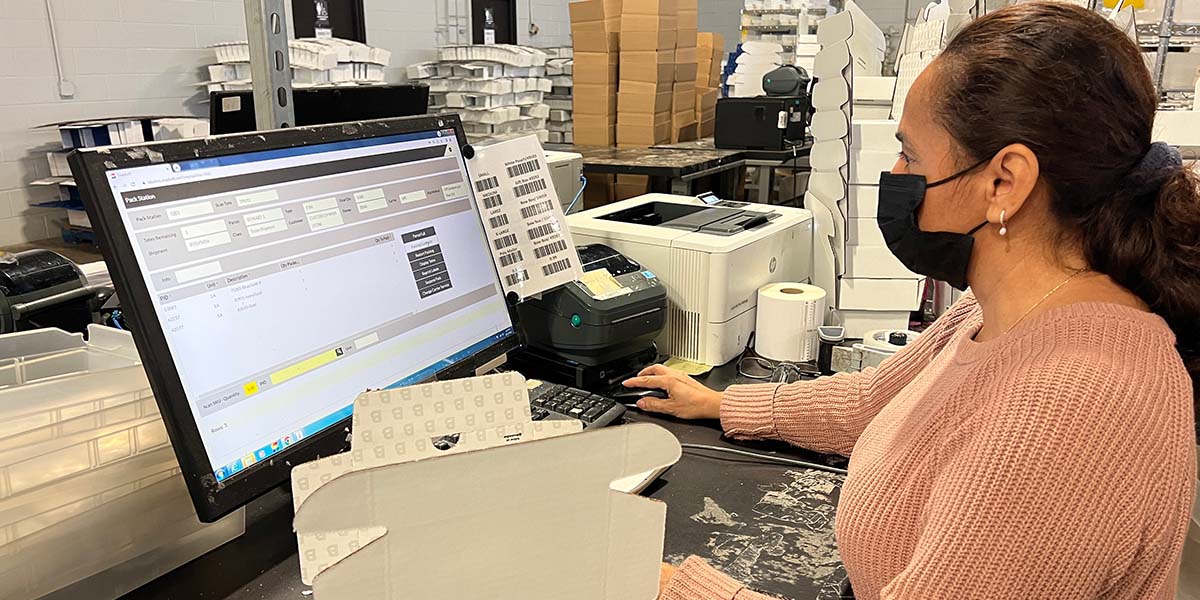

SnapFulfil’s ‘SPIM’ is the favorite (and game changing) form of functionality for Maritza Mejia, Senior Operations & Customer Care Director at BaubleBar, because it facilitates streamlined and highly accurate single order line processing of multiple products. It also works in tandem with any other rules regarding stock availability and picking priority.

Maritza explains: “It’s quickly given us incredible efficiency and noticeable workflow and volume gains. Our picking rate has quickly gone up from 40 to 400 per hour, eliminating the previous bottlenecks and limitations of the old system.

“A custom made-to-order (MTO) program also allows our warehouse associates to easily pick unique items (without unique SKUs and sales tags) and track individual POs, inventory and order fulfilment through the WMS for the first time. We’ve only started scratching the surface, but with the real time data now available it will be our go-to business model and blueprint for the future and will triple the size of our business, for sure.”

Another big and immediate efficiency gain is in full retail compliance labels and shipping via the SnapFulfil WMS, instead of being externally managed. It customizes templates based on order profile, labor and administration costs and automatically generates a SSCC number per carton.

Maritza adds: “We work with demanding big box fulfillers like Bloomingdales, Nordstrom, TJ Maxx, Neiman Marcus, Ross Stores, Zappos, Burlington - and the generic labels created by the old system were basically useless. Our warehouse associates had to stop picking and manually create/print them each time, which was very time consuming and labor intensive.”

BaubleBar’s implementation was handled remotely, giving them further time, money and resource savings and also coincided with a new ERP (NetSuite) and Shopping Cart – both of which directly integrate with SnapFulfil. Maritza and two of her team were also trained up to be Super Users, so they could easily and effectively cascade their system and testing knowledge down to new users accordingly and make Go-Live as seamless as possible.

They were even troubleshooting exceptions themselves online as the big day approached.

Maritza concludes: “Digital implementation initially seems daunting and challenging, but the SnapFulfil team is very diligent and thorough and soon put our minds at ease. We went live and to schedule with more or less zero disruption and they were very clear on what we have, what can further be achieved and the process improvements that go with it. That to me is the essence of a premier WMS system and service, where nothing is too much trouble.

“They also have a very consultative approach and we were able to brainstorm with them and have an input on the likes of the MTO modifications and racking. I also love the fact that they’re willing to let us ramp up and down on SnapFulfil licenses, as during seasonal peaks we now have the demand and capacity to scale up from 15-20 to 100-150 users per day.

“Thanks to our partnership with Synergy and SnapFulfil, we’re now well on the road to optimizing every last part of our DC.”